English

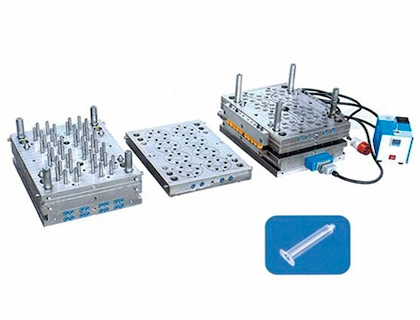

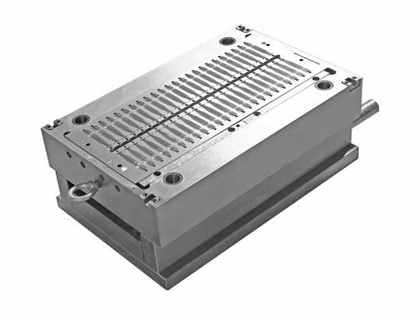

Medical Molds

Medical Equipment Making Machine

Syringe Machine

Needle Machine

Infusion Set Machine

Cannula Making Machine

Medical Injection Machine

Syringe Barrel Printing Machine

Syringe Assembly Machine

AD Syringe Assembly Machine

Safety Syringe Assembly Machine

Syringe Blister Packing Machine

Syringe Pe Packing Machine

Syringe Barrel Printing and Assembly Machine

Needle Assembly Machine

Needle Blister Packing Machine

Scalp Vein Set Assembly Machine

Insulin Pen Needle Assembly Machine

Blood Collection Needle Assembly Machine

Safety Needle Assembly Machine

Medical Tubing Extrusion Machine

Chamber Extruding Machine

Drip Chamber Assembly Machine

Connector Assembly Machine

Flow Regulator Assembly Machine

Automated Medical Tubing Cutter

Infusion Set Automatic Assembly Machine

Cannula Welding Machine

Cannula Diameter Reducing Machine

Double-heads Straightening Machine

Needle Tube Polycondensation Film Machine

Automatic Needle Tube Cutting Machine

Automatic Needle Tube Collocating Machine

Automatic Cannula Grinding Machine

Automatic Cannula Electrolyzing Machine

Automatic Cannula Ultrasonic Cleaning Machine

English

English